Please note: This unit is available as is for immediate sale, however, we have decided to send the machine to the Megabore factory in Taiwan for a makeover, (not a rebuild), where any obvious faults will be corrected, repainted and the latest Fanuc CNC with manual guide software will be fitted.

The Mazak Powermaster 80N CNC Lathe is a heavy-duty turning center designed for large-diameter and long-shaft workpieces, commonly used in industries like oil and gas.

Advanced Capabilities

• High Torque Spindle: Designed for demanding applications, the spindle delivers exceptional torque at low RPMs, making it ideal for cutting tough materials like alloy steels and superalloys.

• Precision Engineering: Linear scales and feedback systems ensure high accuracy and repeatability, critical for aerospace and oilfield components.

• Programmable Tailstock & Steady Rest: Supports long shafts and heavy workpieces, improving stability during machining.

• Mazatrol CNC Control:

• Conversational programming for ease of use

• Supports EIA/ISO G-code for compatibility with CAM systems

• Real-time diagnostics and tool monitoring

Construction & Build

• Massive Bed Casting: Provides rigidity and vibration damping for stable cutting

• Box Ways: Heavy-duty box-type guideways enhance durability and load capacity

• Hydraulic Chuck & Tooling: Enables fast setup and changeover

Optional Accessories

• Live Tooling: For drilling and milling operations on the lathe

• Automatic Tool Presetter: Speeds up setup and improves accuracy

• Bar Feeder or Gantry Loader: For automation and high-volume production

Typical Use Cases

• Machining of:

• Drill collars and stabilizers

• Long shafts and rollers

• Flanges and couplings

• Common in:

• Oil & gas field service shops

• Heavy equipment manufacturing

• Railway and marine industries

• Chuck Size: 38" depending on configuration

• Bar Capacity / Spindle Bore: 21.5

• Swing Over Bed: 42"

• Maximum Turning Diameter: 33"

• Maximum Machining Length: Up to 160"

• Spindle Speed: Up to 300 RPM

• Spindle Motor Power: 45 kW / 60 HP

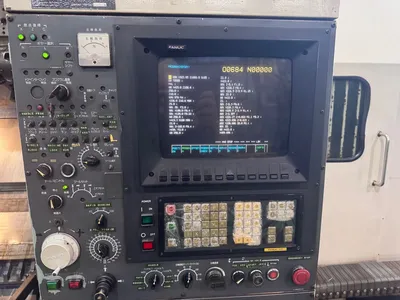

• Control System: Fanuc 11T CNC Control

• Turret Configuration: 12 Station

• 12 station disc turret for heavy-duty cutting

•

⚙️ Features

• Heavy-Duty Machining: Built for high torque and low-speed cutting, ideal for tough materials and large components

• Programmable Tailstock: Enhances precision and automation

• Chip Conveyor: Integrated for efficient chip removal

• EIA/ISO Input Function: Supports standard programming formats

• Optional Enclosures: Fully enclosed covers available for safety and cleanliness

We use cookies to improve your experience. Privacy Policy.