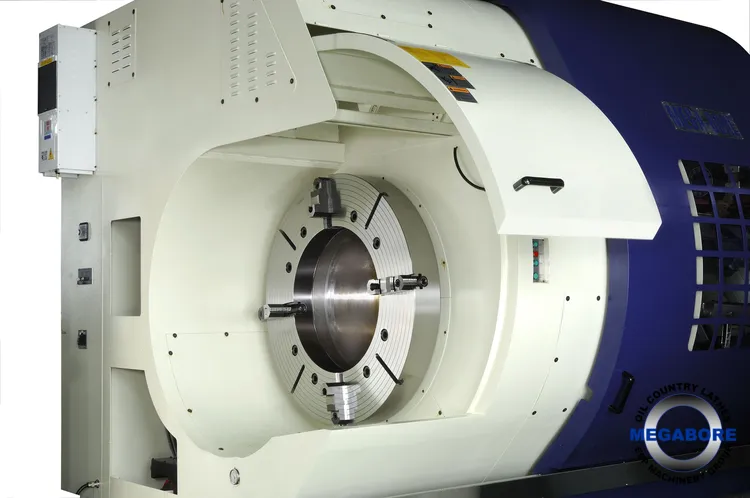

MEGABORE lathes are designed primarily for heavy duty turning operations with dramatic productivity.

The high quality casting construction assures optimum rigidity and stability.

Great horsepower motor provides high torque in low output speed which is excellent for heavy cutting.

BED WIDTH : 1580mm (62.20")

Each machine is manufactured to the highest quality standards.

SA-40 SA-45 SA-50 Number denotes swing over bed in inches.

When comparing Megabore Lathes to other brands check the weights, It is a well known fact that Mass absorbs vibration, this fact is even more important with modern cutting tools.

* One piece bed, 60° slant bed construction ensures maximum stability and convenient chip disposal.

* Alloy steel spindle with opposed taper roller bearings.

* All gears in the headstock are hardened and precisely ground.

* Automatic ranges of spindle speed through pneumatic gear shift.

* Spindle speed ranges are automatically changed by M code.

* Infinitely variable speed are commanded by S code.

* Tool change are commanded by T code.

* Auto lubrication system is equipped for headstock, carriage, and cross-slide.

* Precision tapered roller bearings are equipped on the spindle and the quill.

* The quill is heat treated and precisely ground.

* Internal taper of quill to suit MT#6 dead center or live centre.

* Turcite B anti friction material is applied on cross slide and carriage for reduce friction.

* X and Z axis ballscrews are protected by covers to prevent ingress of swarf / chips and coolant.

ITEM UNIT:......................................................SA-40, SA-45, SA-50

All dimensions in inches

Swing over bed:..............................................37, Opt - 39.76, 43.11

Center height:..................................................23.81, 26.57, 29.92

Swing over cross slide.............................................34.25, 37, 40.35

Distance between centers...........................................27 to 206 inches

BED

Width / Slant angle.....................................................62.20 / 60°

CARRIAGE

Width of cross slide..........................................................23.62

TURRET

Standard tool post..........................................Polygon Disc / VDI disc

No. of tool stations..........................................V12 / Option V8;- V12

Turning Tool Size..........................................................ins 1.25

Boring Tool Size (max.).........................................................2.5

Ballscrew diameter.......................................X axis: 1.96; Z axis: 3.14

TAILSTOCK

Quill type.................................Built-in type, Rotating tail-stock quill

Quill diameter............................................................9.25 inch

Quill travel...................................................................7.87

Internal taper of quill........................................................MT#6

MOTOR

Headstock oil refrigerator

Main spindle....................................................(HP) 50-STD. 60-OPT.

Axis servo.................................KW(HP) X axis: 7(9.387); Z axis: 7(9.387)

Hydraulic tank.........................................................KW(HP) 3.7(5)

Coolant pump........................................................KW(HP) 1.05(1.4)

Controller:.........FANUC 0i-TF series-STD; FANUC 31i-B series / Other required-OPT.

Note:

(1) X and Z axes actual cutting diameter will change when equipped with different

turrets.

(2) Specifications are subject to change without notice for improvement.

Heavy Duty Slant Bed

Swing over Bed.........................................37 inch (Options 40, 43 inch).

Hollow Spindles available.........................................6 inch to 22 inch

Between centers.................................................28 inches to 17 ft.

*FEATURES.

* One piece bed, 60° slant bed construction ensures maximum stability and convenient

chip disposal.

* Alloy steel spindle with opposed taper roller bearings.

* All gears in the headstock are hardened and precisely ground.

* Automatic ranges of spindle speed through pneumatic gear shift.

* Spindle speed ranges are automatically changed by M code.

* Infinitely variable speed are commanded by S code.

* Tool change are commanded by T code.

* Auto lubrication system is equipped for headstock, carriage, and cross-slide.

* Precision tapered roller bearings are equipped on the spindle and the quill.

* The quill is heat treated and precisely ground.

* Internal taper of quill to suit MT#6 dead center or live center.

* Turcite B anti friction material is applied on cross slide and carriage for reduce

friction.

* X and Z axis ballscrews are protected by covers to prevent ingress of swarf / chips

and coolant.

* V12 turret.

* Rotating tailstock quill with 235mm diameter.

* Motorized tailstock body and quill movement.

* FANUC 0i-TF series complete with manual guide and thread repair.

* Front chip conveyor

We use cookies to improve your experience. Privacy Policy.