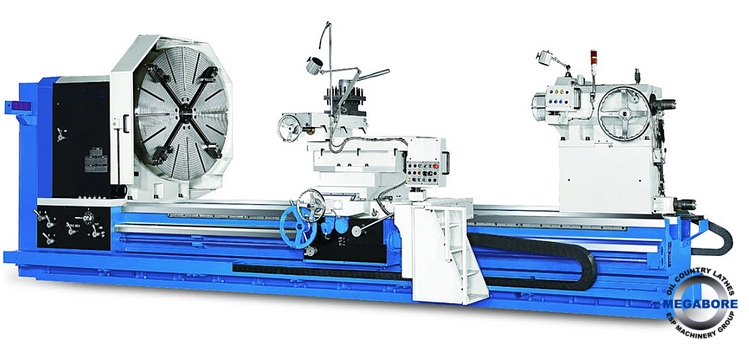

* One piece bed, floor type casting.

* 4 shear bed way with dual way centre guide plus front lateral way for carriage support under cutting.

* All ways are hardened and ground.

* Alloy steel spindle with opposed taper roller bearings.

* Hardened and ground gears, shafts.

* Electromagnetic spindle brake.

* Variable spindle speeds in 4 automatic ranges through pneumatic shifting.

* 6-way rapid traverse and power feed to top slide.

* Totally enclosed universal inch / metric gear box.

* Carriage position device.

* Dual voltage spindle motor, 40 to 100 HP.

BED WIDTH : 1100mm (43.31")

PH series PH-50 PH-60 PH-70 PH-80

Swing over bed 1,300mm 1,550mm 1,800mm 2,050mm

Swing over cross slide(Long carriage) 785mm 1,035mm 1,285mm 1,535mm

Swing over cross slide(Short carriage) 985mm 1,225mm 1,470mm 1,720mm

Distance between centers 3,000mm~12,000mm in 40" increments

Spindle nose A2-15~A2-40

Spindle bore 7"~24" 7"~30" 9"~32" 9"~32"

Spindle motor Standard-40HP ; Option-50HP,60HP,75HP,100HP

Outstanding Features

Standard Accessories

Specification

BED

Width (W/O auxiliary guide) mm (in.) 1100 (43.30)

Width (W auxiliary guide) mm (in.) 1270 (50.00)

CARRIAGE

Cross slide travel(Long carriage) mm (in.) 1170 (46.06)

Cross slide travel(Short carriage) mm (in.) 415 (16.33)

Compound tool post travel mm (in.) 600 (23.62)

4-way tool post width mm (in.) 310 (12.20)

THREAD FEED RANGE

Longitudinal feed mm/rev (in.rev) 0.045~2.55 (0.0018~0.1)

Cross feed mm/rev (in.rev) 0.023~1.28 (0.0009~0.05)

Longitudinal rapid feed mm/rev (in.rev) 2000 (78.74)

Cross rapid feed mm/min (in/min) 1270 (50.00)

Metric thread mm (kinds) 1~56 (60)

Inch thread TPI (kinds) 1/2~28 (60)

Module thread MOD (kinds) 0.25~14 (60)

Diamteral pitch thread DP (kinds) 2~112 (60)

Pitch of leadscrew mm (TPI) 12 (2)

TAILSTOCK

Quill diameter mm (in.) 235 (9.25)

Quill travel mm (in.) 200 (7.87)

Inner taper of quill MT#6

Bearing surface on the bed ways mm (in.) 660 (25.98)

MOTOR

Main spindle motor KW (HP) 29(40)-STD.

37(50) / 44(60) / 55(75) / 74(100) / 11(150) / 149(200)-OPT

Coolant pump motor KW (HP) 0.37 (0.5)Note :

(1) X and Z axes actual cutting diameter will change when equipped with different turrets.

BED

Width (W/O auxiliary guide)...................................mm (in.) 1100 (43.30)

Width (W auxiliary guide).....................................mm (in.) 1270 (50.00)

CARRIAGE

Cross slide travel(Long carriage).............................mm (in.) 1170 (46.06)

Cross slide travel(Short carriage).............................mm (in.) 415 (16.33)

Compound tool post travel......................................mm (in.) 600 (23.62)

4-way tool post width..........................................mm (in.) 310 (12.20)

THREAD FEED RANGE

Longitudinal feed.............................mm/rev (in.rev) 0.045~2.55 (0.0018~0)

Cross feed.................................mm/rev (in.rev) 0.023~1.28 (0.0009~0.05)

Longitudinal rapid feed................................mm/rev (in.rev) 2000 (78.74)

Cross rapid feed.......................................mm/min (in/min) 1270 (50.00)

Metric thread mm..................................................(kinds) 1~56 (60)

Inch thread TPI.................................................(kinds) 1/2~28 (60)

Module thread MOD..............................................(kinds) 0.25~14 (60)

Diametral pitch thread DP........................................(kinds) 2~112 (60)

Pitch of leadscrew..................................................mm (TPI) 12 (2)

TAILSTOCK

Quill diameter..................................................mm (in.) 235 (9.25)

Quill travel....................................................mm (in.) 200 (7.87)

Inner taper of quill..........................................................MT#6

Bearing surface on the bed ways................................mm (in.) 660 (25.98)

MOTOR

Main spindle motor KW (HP) 29(40)-STD. 37(50) / 44(60) / 55(75) / 74(100) / 11(150)

/ 149(200)-OPT

Coolant pump motor...............................................KW (HP) 0.37 (0.5)

Note:

(1) X and Z axes actual cutting diameter will change when equipped with different

turrets.

(2) Specifications are subject to change without notice for improvement

Center distances available up to 40 ft.

Hollow spindles from 6 inches to 32 inches.

STANDARD ACCESSORIES

* 1 dead centre, MT #6.

* 2-speed tailstock quill (manual).

* One piece stainless steel leadscrew cover.

* Coolant pump.

* Follow type splash guard.

* Rear side chip and water collect plate.

* Thread chasing dial.

* Water and oil collect plate under apron.

* Work lamp.

OUTSTANDING FEATURES

* One piece bed, floor type casting.

* 4 shear bed way with dual way centre guide plus front lateral way for carriage

support under cutting.

* All ways are hardened and ground.

* Alloy steel spindle with opposed taper roller bearings.

* Hardened and ground gears, shafts.

* Electromagnetic spindle brake.

* Variable spindle speeds in 4 automatic ranges through pneumatic shifting.

* 6-way rapid traverse and power feed to top slide.

* Totally enclosed universal inch / metric gear box.

* Carriage position device.

* Dual voltage spindle motor, 40 to 100 HP.

* Pressurized one shot lube system for cross slide and carriage.

* 1 dead centre, MT #6.

* 2-speed tailstock quill (manual).

* One piece stainless steel leadscrew cover.

* Coolant pump.

* Follow type splash guard.

* Rear side chip and water collect plate.

* Thread chasing dial.

* Water and oil collect plate under apron.

Chucks will be quoted to client specifications

We use cookies to improve your experience. Privacy Policy.