Megabore, hollow spindle Lathes PB Series offer swings over bed of 45-50 and 60 inches. Hollow Spindles 6″ – 30″ clearance.

The PB series of Heavy Duty Lathes were developed and designed to provide optimum performance with high cutting power while providing versatility for use in a wide range of industries : general purpose machine shops, mining industry, power industry, oil industry, paper plants, and shipyards, etc.

The PB series feature the most modern designs, providing high efficiency and easy operation.

Note, as most clients for this type of machine are the oil industry general specifications are imperial.

Detailed specifications are metric.

ITEM UNIT PB-45 PB-50 PB-60

CAPACITY

Centre height mm (in.) 590 (23.22) 650 (25.59) 775 (30.51)

Swing over bed mm (in.) 1165 (45.86) 1280 (50.39) 1530 (60.23)

Swing over cross slide mm (in.) 840 (33.07) 950 (37.40) 1210 (47.63)

Swing over gap mm (in.) 1610 (63.38) 1730 (68.11) 1980 (77.95)

Gap width from headstock(opt.) mm (in.) 600 (23.62)

Distance between centres mm (in.) 1500 (59.05), 2000 (78.74), 3000 (118.11),

4000 (157.48), 5000 (196.85), 6000 (236.22),

7000 (275.59), 8000 (314.96), 9000 (354.33),

10000 (393.70), 11000 (433.07), 12000 (472.44)

BED

Width (W/O auxiliary guide) mm (in.) 715 (28.14)

Width (W auxiliary guide) mm (in.) 800 (31.49)

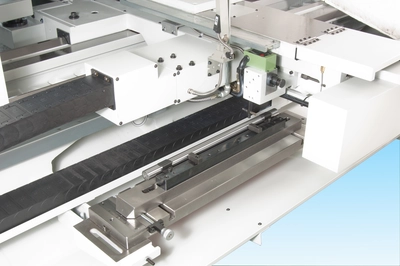

CARRIAGE

Cross slide travel mm (in.) 800 (31.49)

Compound tool post travel mm (in.) 500 (19.68)

4-way tool post width mm (in.) 255 (10.03)

THREAD FEED RANGE

Longitudinal feed mm/rev (in.rev) 0.045~2.55 (0.0018~0.1)

Cross feed mm/rev (in.rev) 0.023~1.28 (0.0009~0.05)

Longitudinal rapid feed mm/rev (in.rev) 2000 (78.74)

Cross rapid feed mm/min (in/min) 1270 (50.00)

Metric thread mm (kinds) 1~56 (60)

Inch thread TPI (kinds) 1/2~28 (60)

Module thread MOD (kinds) 0.25~14 (60)

Diamteral pitch thread DP (kinds) 2~112 (60)

Pitch of leadscrew mm (TPI) 12 (2)

TAILSTOCK

Quill diameter mm (in.) 145 (5.70)

Quill travel mm (in.) 200 (7.87)

Inner taper of quill MT#6

Bearing surface on the bed ways mm (in.) 600 (23.62)

MOTOR

Main spindle motor KW (HP) 22(30)-STD.

29(40) / 37(50)-OPT.

Coolant pump motor KW (HP) 0.1 (0.125)

Single piece bed casting resting entirely on the floor for maximum rigidity

Massive heavy duty headstock

6-Ways power feed/rapid feed

Top slide is hardened and precision ground

Natural and removable gaps

OPTIONAL ACCESSORIES

Headstock clutch and brake

Semi automatic threading and copy system for the oil industry

Chucks and Steadies supplied to Client requirements.

We use cookies to improve your experience. Privacy Policy.