MCV C-frame includes box way and linear way. The MCV box way is a popular choice for general part making involving heavy milling operation. It is designed to handle some of the typical jobs performed in general shops that require a bigger travel, high torque (from the gearbox), and consistent performance. The MCV linear way has the characteristic of small foot print, rigid construction, and well-balanced cutting power.

The MCV machining center is a matured machine with solid all-around performance. Additional accessories such as the Renishaw tool presetter, parts probe, Heidenhain scales, various spindle speed and torque selection, and a combination of different pressure coolant through the spindle are all available for a special configuration. The low maintenance rate of 0.1% in the first year had been the benchmark for LYMCO machines.

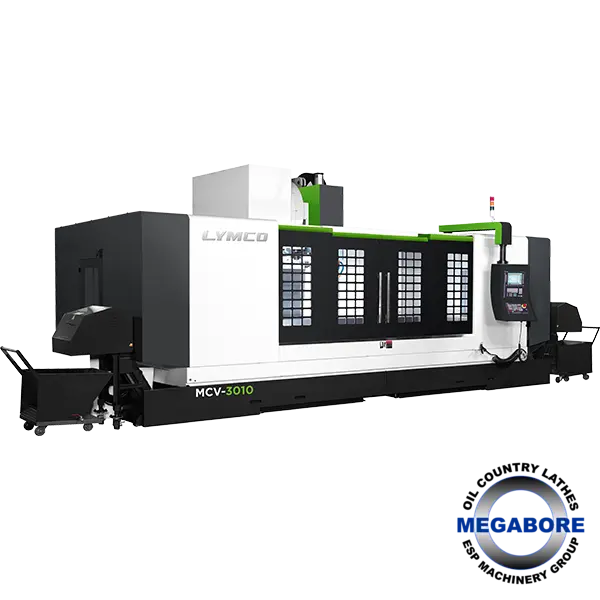

MCV-168 MCV-188 MCV-2010 MCV-2510 MCV-3010

X axis (mm) 1600 1800 2000 2500 3000

Y axis (mm) 800 800 1000 1000 1000

Z axis (mm) 700 700 800 800 800

Table loading capacity (kgs) 2000 2200 3000 3200 4000

Table size (mm) 1,700 X 815 1,900 X 850 2,200 X 1,000 2,700 X 1,000 3,100 X 1,000

Max. spindle speed (rpm) 6000 (OP. 8000) I 5500 6000 (OP. 8000) I 5500 6000 (OP. 8000) I 5500 6000 (OP. 8000) I 5500 6000 (OP. 8000) I 5500

Spindle drive motor (kw) 15 / 18.5 (18 / 22.5) 15 / 18.5 (18 / 22.5) 15 / 18.5 (18 / 22.5) 15 / 18.5 (18 / 22.5) 15 / 18.5 (18 / 22.5)

Rapid on X,Y,Z (mm/min) 15000 15000 15000 15000 15000

Cutting feedrate (mm/min) 1-5,000 1-5,000 1-5,000 1-5,000 1-5,000

Machine weight (kgs) 15000 15500 20000 22000 24500

We use cookies to improve your experience. Privacy Policy.