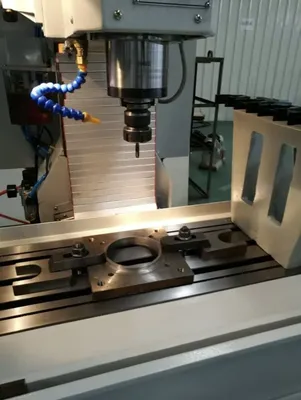

SP2211-T cnc mini vertical milling machine.

Designed for manufacture small parts where budget is important.

With linear guide-way, all functions as per a normal vertical machine center.

Tools can be changed automatically

* Used for machining box parts, shell parts, disc-shaped parts.

* Column and guide way are ground precisely.

* Control Standard GSK.

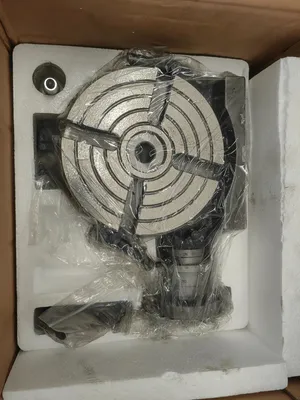

* 4 pcs tool station on worktable

* Additional Computer Socket

* Powerful Brushless Motor & High Precision Axes Movements

* Fine Feedings on Every Directions

* Robust Construction & Stable Performance

* Professional Electronic System

* Cabinet Safety Lock & Considerable Safety Signs

Model

SP2211-T

Size of Worktable 900 x 240 mm

Distance from Spindle Nose to Worktable 50 - 450 mm

Distance from Spindle Center to Column 297 mm

X Axis Travel 530 mm

Y Axis Travel 290 mm

Z Axis Travel 500 mm

Spindle taper BT30

Maximum loading weight on work table 60 Kgs

Maximum spindle speed 6000 r/min

Spindle motor power 2.2

Feeding motor power: X/Y/Z axis 1Kw / 1kw / 1Kw

Rapid Feeding Speed X/Y/Z Axis 6 m/min

Feeding Speed 0-2,000 mm/min

T-slot Width 16 mm

T-slot Amount 3

T-slot Gap 60 mm

Minimum set unit of feeding X/Y/Z axis 0.01mm

Maximum tool size Φ60 x 175 mm

Tool magazine capacity 4 pcs

Tool clamping and tightening way Clamp by disc spring and tool-released pneumatically

Maximum loading weight of tool 3.5 Kgs

Voltage and Frequency Customized

Overall Dimension (LxWxH) 1,640 x 1,250 x 1,950 mm

Net Weight 760 Kgs

We use cookies to improve your experience. Privacy Policy.