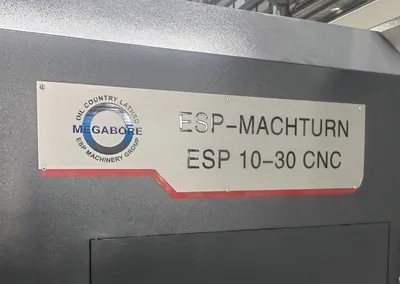

Introducing the Next-Generation Lathe: A Perfect Blend of Manual Flexibility, and CNC Precision

Overview

Imagine a lathe that combines the tactile feel of a manual machine with the precision and efficiency of a full CNC system. This innovative lathe design is aimed at operators who seek versatility in their machining processes, making it ideal for both small-batch production and complex tasks.

Key Features

1. CNC Functionality**:

- The CNC capabilities of this lathe significantly enhance productivity, especially for repetitive tasks such as:

- **Thread Cutting**: Achieve consistent and precise threads without manual adjustments.

- **Taper Turning**: Easily create tapered shapes with high accuracy.

- **Chamfering**: Effortlessly add chamfers to edges for improved part aesthetics and functionality.

- **Tool Changing**: Automatic tool changes streamline the production process, minimizing downtime.

2. **Manual Flexibility**:

- While the lathe excels in CNC mode, it also allows operators to switch to virtual manual control for one-off jobs or intricate adjustments, catering to a wide range of machining needs.

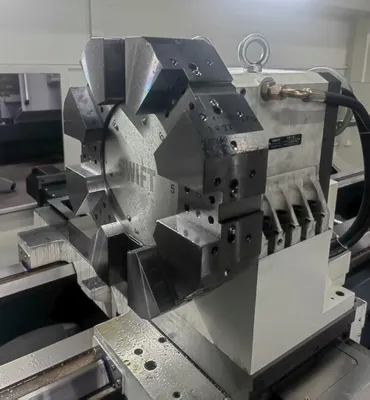

3. **8-Station Turret**:

- Equipped with an 8-station turret, this lathe allows for quick tool changes and efficient multi-tool operations, reducing setup time and enabling varied machining operations without the need to constantly reconfigure.

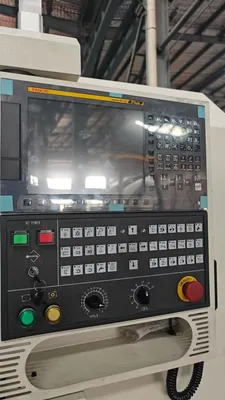

4. **High-Quality Control System**:

- The lathe comes standard with the respected **Fanuc OI-TF CNC control system**, which is known for its reliability, user-friendly interface, and extensive programming capabilities.

- **Manual Guide i Function**: This feature simplifies the programming process, making it accessible for operators at all skill levels. It provides step-by-step guidance for creating CNC programs, ensuring that users can take full advantage of the machine’s capabilities.

5. **Affordability**:

- Despite its advanced features, this lathe is competitively priced, making it an attractive option for both small workshops and larger manufacturing facilities looking to enhance their machining capabilities without breaking the bank.

6. **Chucks and Steadies**:

- The machine includes various chucks and steadies, providing versatility for different workpiece sizes and types. This ensures stability and precision during operations, particularly for larger or irregularly shaped parts.

The machine is available for world wide sales. ESP are a well known with its Megabore brand of CNC and manual lathes which are used throughout the world.

Universal Heavy Duty CNC Lathe-ST61100 With Fanuc-OI-TF Manual Guide software.

System Voltage:415V,50HZ,3 PHASE +Transformer

Configuration: Fanuc OI-TF with manual guide i function.

4 Jaw Chuck 800mm Fixed Steady 8-station servo turret,

hydraulic station

Max. load capacity:4T

Max swing over bed:1000mm

Max swing over cross slide:680mm

Center distance:3M

Guideway width:650mm

Spindle bore:∮105mm

Spindle nose:C11

Spindle center height:500mm

Spindle taper: Metric 120/1:20

Mode of spindle speed:3 gears, infinitely variable

speed within gears

Range of spindle speed:Low range (L): 25-100 /

Mid range (M): 80-260 / High range (H): 240-700

Power of Spindle:15KW

Max.traverse of X/Z:X:520/Z:2750mm

X/Z rapid traverse:4000/6000mm

Tailstock quill diameter:120mm

Tailstock quill travel:290mm

Tailstock quill taper:MT6

Tool shank size:32*32mm

Chuck:K11-400 Three-jaw Chuck

Overall dimensions(L×W×H):5300×2200×2000mm

Machine weight:7.5T

Standard accessories:

FANUC system, Eight-station electric tool turret,

three-jaw chuck, manual tailstock, automatic

lubrication, cooling system, semi-enclosed

protective cover, center stand, follower rest

4 Jaw Chuck

8 Station Turret

Steadies

Fanuc-OI-TF Manual Guide software

We use cookies to improve your experience. Privacy Policy.