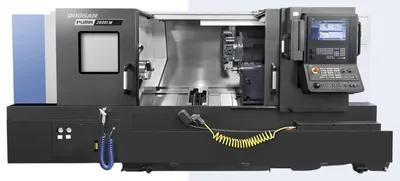

The DOOSAN GT 2600M is a CNC turning center known for its precision, efficiency, and versatility in machining. It's a popular choice in industries like automotive, aerospace, and metalworking for producing intricate components with high accuracy and repeatability.

This machine is like new, apart from a few test pieces it has never been in production.

Here's a more detailed description:

Despite its capabilities, the machine has a relatively compact footprint, allowing it to fit into various workshop layouts.

The GT 2600M is designed for demanding applications requiring tight tolerances and excellent surface finishes.

It handles a wide range of workpiece sizes and materials, making it suitable for diverse manufacturing needs.

Features like a 12-position turret for quick tool changes and a powerful spindle motor contribute to reduced downtime and increased productivity.

The machine incorporates features that simplify operation and programming, making it accessible to operators with varying experience levels.

The 22 kW spindle motor provides ample power for turning operations, with a maximum speed of 3500 RPM.

Specific Capabilities:

Turning Length: 790 mm

Turning Diameter: 481 mm

Maximum Diameter Above Bed: 780 mm

Maximum Diameter Above Slide: 630 mm

Bar Capacity: Up to 76mm

OVER $30k OF TOOLING INCLUDED WITH THE MACHINE.

Suit new buyer.

Basic Specifications

• 630mm Swing Over Bed

• 460mm Swing Over Saddle

• 610mm Turning Length

• 410mm Turning diameter

• 3600 (0.0010 Resolution) C Axis

• 220kg Main Spindle Capacity. 520kg Shaft Work Capacity

Main Spindle

• 81mm Bar Capacity

• 250mm Ø Hydraulic Chuck

• 3500RPM Spindle Speed

• 22kW Spindle Power

• 633Nm Spindle Torque

Tailstock

• MT5

• 100mm Quill Ø

• 100mm Quill Travel

• Programmable Positioning

Turret

• BMT 55 Tool Mounting

• 5000rpm Live Tool Speed

• 5.5kW Live Tool Power

• 47.1Nm Live Tool Torque

• 12 Station Turret

• 25mm Square / 40mm Ø Tool Capacity

• ER25 Live Tool Collet Size

• Eppinger Preci-Flex Tooling System

CNC Control

• Doosan Fanuc I Series (0i-MD) CNC Controller

• 10.4” Colour LCD Monitor

• Rigid-synchronised tapping

• Custom Macro B

• Ethernet Interface

• RS232 Interface

• USB & PCMCIA Memory Card Slot

• Doosan Ezi Guide “I” Conversational software:

• Graphical Turning Cycles

• Graphical Milling Cycles

• Full 3D Graphical Simulation

• Onboard G & M code assistance

• + more

Standard Equipment - Included

• 3 Jaw Hydraulic Power Chuck

• Chuck Cleaning Air Blast

• Eppinger rotary tool holders with Preci-Flex adapter set

• Coolant supply equipment

• Foot switches

• Transformer

• Full enclosure chip and coolant shield with front door interlock

• Hand tool kit

• Automatic lubrication equipment

• Comprehensive manuals incorporating, Operation, Maintenance, Programming, Spare Parts Diagrams, Hydraulic Schematics, Electrical Schematics and Ladder Diagrams.

• Safety name plates / tags where required

• Risk assessment

• Work light

Optional Equipment Included

• Chuck open close confirmation proximity switches

• Chip Conveyor (Side Discharge, Hinged Belt)

• Auto Tool Setter (Hydraulically operated)

• Coolant Oil Skimmer

• 7 Bar High Pressure Coolant

• Barfeed Interface

• Programmable Tailstock

We use cookies to improve your experience. Privacy Policy.